How to choose the right rock drill bit in drilling and exploration

In drilling and exploration operations, rock drill bits are the core tools. Choosing the right drill bit is crucial to improving operating efficiency, reducing costs and ensuring safety. This article will help you choose the best rock drill bit. It considers factors like drill bit type, formation type, size, durability, drilling technology, safety regulations, maintenance, replacement, and actual selection.

1. Rock Drill bit type and characteristics

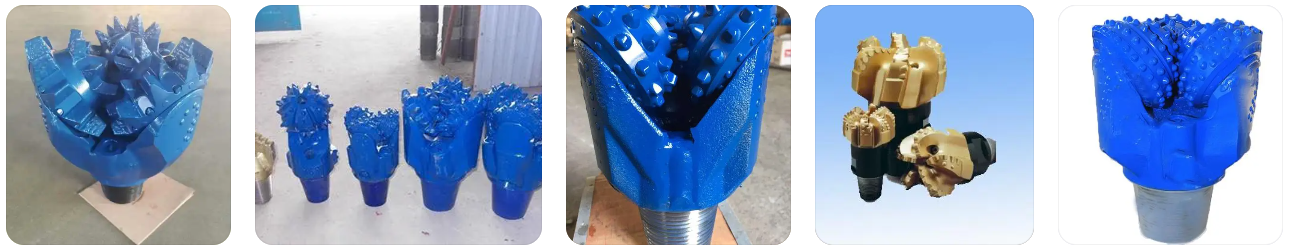

Many types of rock drill bits include tricone drill bits, diamond drill bits, PDC drill bits, etc. Each drill bit has its own unique characteristics and applicable scenarios.

Diamond drill bits are ideal for hard rock, while PDC drill bits are better suited for soft and medium hard rock. for hard rock formations, while PDC drill bits are more suitable for soft rock and medium hard rock formations. To choose the right drill bit, you must understand the various types available. Then, you can select the one that is most suitable for the specific conditions you are working in.

2. Formation type and rock drill bit

The difference in formation type directly affects the choice of drill bits. Drilling hard rock needs tough drill bits, while drilling soft rock needs bits that cut well and remove debris easily. To choose the right drill bit, you must consider the type of rock, its hardness, and how fractured it is.

You also need to know details about the formation you're drilling into. This information will help you select the best drill bit for the job. This will help you pick the best drill bit for the job.

3, Rock drill bit size and drilling requirements

You should determine the selection of rock drill bit size according to drilling requirements and equipment conditions. The borehole diameter, well depth, and the power and torque of the drilling equipment will affect the selection of the drill bit. The drill bit should be the same size as the hole. Consider the weight it can handle and how well it cuts.

4,Rock drill bit durability and cost

The durability of the rcok drill bit directly affects the drilling cost and operating efficiency. A drill bit with good durability can reduce the number of replacements, reduce operating costs, and improve operating efficiency. When choosing a drill bit, you should consider its durability, price, and cost-effectiveness comprehensively.

5, drilling technology and Rock drill bit selection

Different drilling technologies will also affect the selection of rock drill bits. Different drilling methods, such as rotary, impact or vibration, require different drill bits. When choosing a drill bit, make sure it matches the drilling technology being used. Consider the characteristics of the drill bit and the drilling technology to ensure compatibility.

6, safety regulations and Rock drill bit standards

You must follow relevant safety regulations and standards when selecting a rock drill bit. The drill bit should comply with industry standards and have the necessary safety certification to ensure safety during the operation. In addition, attention should be paid to the use environment and conditions of the drill bit to avoid using drill bits or operating methods that do not meet the regulations.

7,Rock drill bit maintenance and replacement

The maintenance and replacement of the drill bit are also factors that need to be considered during the selection process. Proper maintenance and care can extend the service life of the drill bit and improve operating efficiency. At the same time, when the drill bit is worn or damaged, it should be replaced in time to avoid affecting the normal progress of the drilling operation.

8, choose in combination with actual conditions

When selecting a rock drill bit, it is necessary to comprehensively consider the above factors and make a selection based on the actual operation situation. In the selection process, the operation requirements, formation conditions, equipment conditions, cost-effectiveness and other factors should be fully evaluated to select the most suitable drill bit type and specifications.

In short, choosing a suitable rock drill bit is a key step in drilling and exploration operations. By understanding the knowledge of drill bit types and characteristics, formation types and drill bits, drill bit sizes and drilling requirements, drill bit durability and cost, drilling technology and drill bit selection, safety regulations and drill bit standards, and drill bit maintenance and replacement, and making choices based on actual conditions, you can improve operational efficiency, reduce costs and ensure safety.

Mobile:

Mobile: E-mail:

E-mail: